KUROSE Spiral Heat Exchanger has unique shape.

Advantages

・Strong on customized solutions

・Low maintenance cost due to easy access

・Compact high-efficiency heat exchanger (CHE)

・Design experience since 1961

We have prepared 2 or 3 types of spirals for each of the three series.

Basic structure (Type1)

Type 1 has two concentric spiral channels, one for each fluid.

The spiral channels provide optimum heat transfer and flow conditions for a wide variety of fluids, while keeping the overall size to a minimum.

Two phase application (Type 2)

Vapor in cross flow and cooling medium in spiral flow. This flow direction can achieve extremely low vapor side pressure drop.

And large flow cross-section can accept large vapor volumes.

Also, short height of cross flow section is suitable in liquid to liquid duty with large flow imbalance.

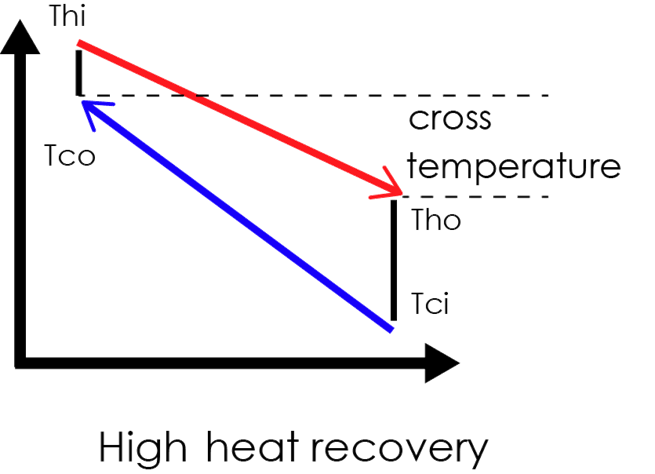

Handle crossing-temperature condition in a single spiral

The fully countercurrent system(KSH-1) is able to exchange heat even if temperature difference is extremely close.

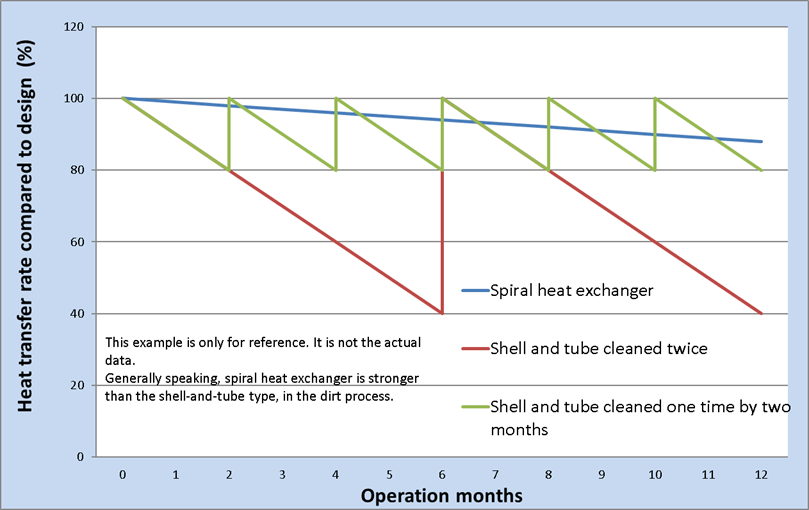

Long time operation is possible

Spiral is very good at using with fluids that tend to cause fouling. Single channel geometry reduce the fouling, and it called “self-cleaning”

Self-cleaning means that when fouling occur in spiral channel, taking it away from. Because the entire flow have to pass through fouling section.

It means that velocity of fouling-section increase. So scrubbing effect will happen.

High Overall Heat Transfer Coefficient

Spiral flow passage easily creates turbulent flow.

Optimum flow speed can be gained by selecting the most suitable spiral channel.

High Overall Heat Transfer Coefficient can be achieved.

Less maintenance

Generally, when install the spiral type, to cut down maintenance cost.

Compare that with any other heat exchanger

* This example is only for reference. It is not the actual data.

* This example is only for reference. It is not the actual data.Generally speaking, spiral heat exchanger is stronger than the shell- and-tube type, in the dirt process.

Space Saving

SHE equipment volume is far compact comparing to Tubeler Heat Exchanger.

Plant space can be saved and plant initial cost can be saved.